- Home

- Industry Solutions

Industry Solutions

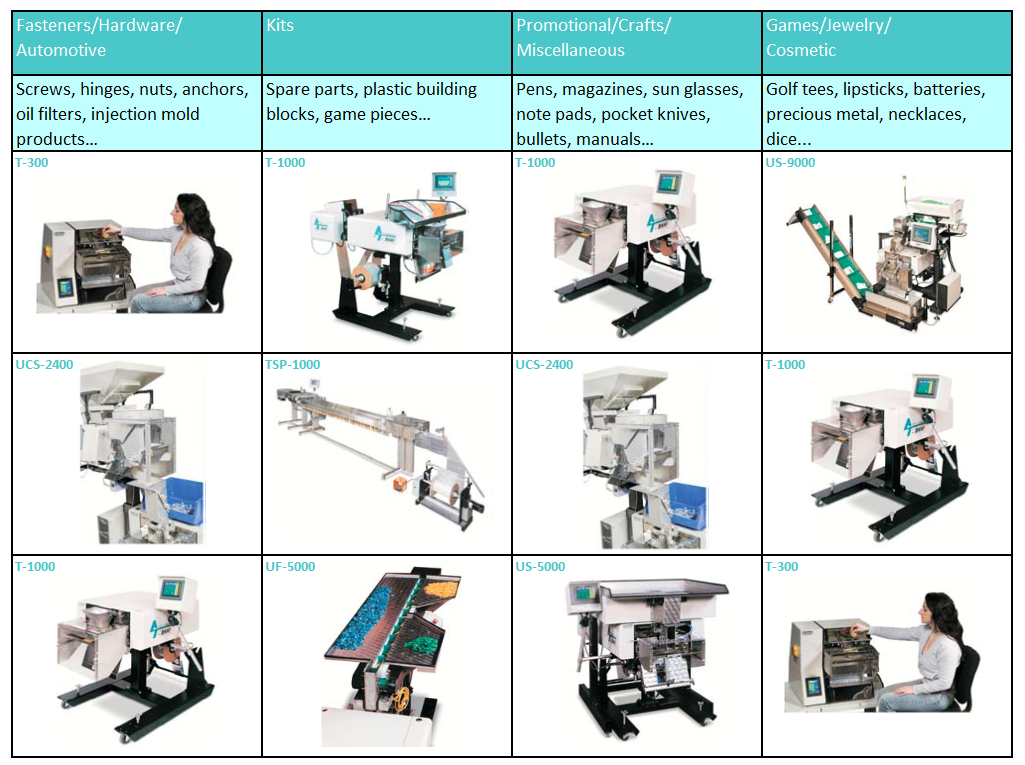

APPI can provide packaging solutions for any industry. If you need guidance, our expert salesmen can guide you toward the perfect system. Their dedication leads them to visit facilities, analyze your space, evaluate your product, and come up with the perfect solution for you! However, we want to be able to help guide you in the right direction from the table below.

Here are a few examples of bagging machines that are often used for some general product categories. The list is not comprehensive! Tell us about your application product.

Click on the "Watch Now" icon to see a video about Advanced Poly's Industry Solutions"

Main Menu

- Quick Ship Equipment

- T-1000 Production Baggers

- T-1000 Options and Accessories

- Tabletop Baggers

- Tabletop Baggers Options and Accessories

- Infeed Conveyors

- Takeaway Conveyors

- Printers

- Printer Accessories

- Ribbon

- Check Weigh Scales

- Counting Scales

- Part Counters

- Part Counter and Scale Accessories

- Replacement Repair Parts

- Used Equipment

- Custom Bags

- Stock Bags

- Industry Solutions

- Engineering Services

- Repairs, Installations, and Service

- Manuals

- Free Products

- Specialty Film

- Overstock Bags

- Installations

- Machine Options

Short Code:

Credit Limit:

Current Balance:

Watch Now

Watch Now