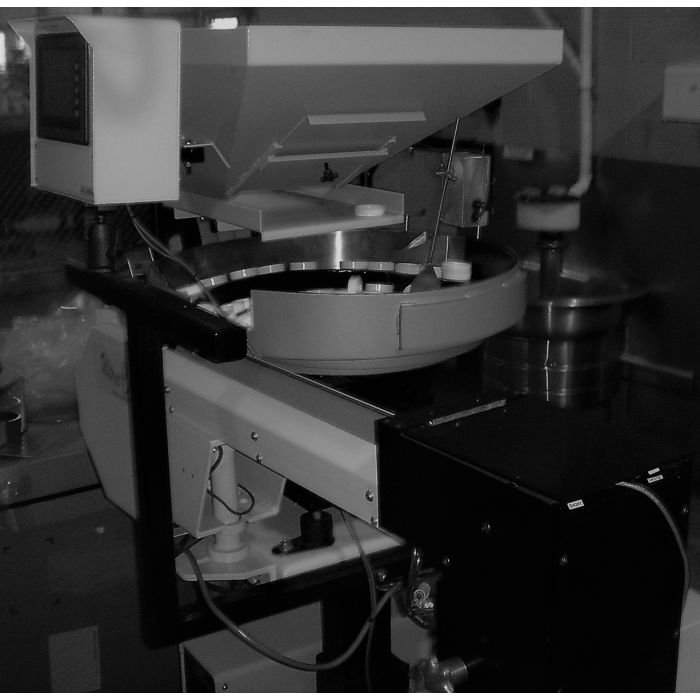

UC-2400 Parts Counting System, Complete w/ ONE UC-2400 Part Counter, T-1000-S14 Advanced Poly-Bagger, Ti-1000Z Inline Thermal Printer, UF-2000 Takeaway Conveyor This system is a perfect industry solution for counting parts (no weighing) such as fasteners

Availability: In stock

Quick Overview

Product code: T-SYSUC2400System

UC-2400 Parts Counting System, Complete w/ ONE UC-2400 Part Counter, T-1000-S14 Advanced Poly-Bagger, Ti-1000Z Inline Thermal Printer, UF-2000 Takeaway Conveyor

This system is a perfect industry solution for counting parts (no weighing) such as fasteners, electrical components, small molded parts and crafts items. Advanced Poly will evaluate your products by running them through our parts counters to confirm speed, accuracy, bag specification and system specifications. With this valuable information, you can decide whether this is a good solution for your company.

Advanced Poly will configure each element of this system to produce the best production and accuracy results. For instance, vibratory bowl size can be from 15 to 36 inches based on your part size and we offer custom fabricated bowls for larger or unusual shaped parts. We offer reject gates, bulk "pre-feeder" hoppers, stack LED lights and other options for the parts counters. The bagger can be configured based on the smallest and largest bag size to optimize the opening consistency and other options added based on the weight or other characterist ics of the product. The printer is optional, but can also be configured with higher resolutions up to 600dpi and connection requirements. Finally, the conveyor can be configured based on the size of the bagged product, height of the discharge and other down-stream operations.

As a "stock" system, our UC-2400 system includes standard options and accessories to package a wide variety of fasteners and hardware. It is simple to setup (less than 5 minutes for new product) and offers job save/recipes for changeover in less than 2 minutes based on the experience of the operator. This system is one of our most popular systems for smaller counts (less than 50 parts per bag), of the same part per bag.

This system can support up to four parts counters simply by placing them into position and connecting them with a single cable, making this system great for kits up to 4 part number per bag.

Please contact APP Machine Sales for more information on this "Industry Solution" System. You can also find our "Product Evaluation" services under the Free Products group. Simply download, complete the form and send it to: MachSales@advancedpoly.com. We will then promptly provide a custom ized quote for the system (budgetary) and after evaluating product sent to us, a confirmed quote with complete equipment specifications, suggested bag sizes and estimated speeds and accuracy.

Details UC-2400 Parts Counting System, Complete w/ ONE UC-2400 Part Counter, T-1000-S14 Advanced Poly-Bagger, Ti-1000Z Inline Thermal Printer, UF-2000 Takeaway Conveyor This system is a perfect industry solution for counting parts (no weighing) such as fasteners, electrical components, small molded parts and crafts items. Advanced Poly will evaluate your products by running them through our parts counters to confirm speed, accuracy, bag specification and system specifications. With this valuable information, you can decide whether this is a good solution for your company. Advanced Poly will configure each element of this system to produce the best production and accuracy results. For instance, vibratory bowl size can be from 15 to 36 inches based on your part size and we offer custom fabricated bowls for larger or unusual shaped parts. We offer reject gates, bulk "pre-feeder" hoppers, stack LED lights and other options for the parts counters. The bagger can be configured based on the smallest and largest bag size to optimize the opening consistency and other options added based on the weight or other characterist ics of the product. The printer is optional, but can also be configured with higher resolutions up to 600dpi and connection requirements. Finally, the conveyor can be configured based on the size of the bagged product, height of the discharge and other down-stream operations. As a "stock" system, our UC-2400 system includes standard options and accessories to package a wide variety of fasteners and hardware. It is simple to setup (less than 5 minutes for new product) and offers job save/recipes for changeover in less than 2 minutes based on the experience of the operator. This system is one of our most popular systems for smaller counts (less than 50 parts per bag), of the same part per bag. This system can support up to four parts counters simply by placing them into position and connecting them with a single cable, making this system great for kits up to 4 part number per bag. Please contact APP Machine Sales for more information on this "Industry Solution" System. You can also find our "Product Evaluation" services under the Free Products group. Simply download, complete the form and send it to: MachSales@advancedpoly.com. We will then promptly provide a custom ized quote for the system (budgetary) and after evaluating product sent to us, a confirmed quote with complete equipment specifications, suggested bag sizes and estimated speeds and accuracy.

Write Your Own Question

| Free Products | No |

|---|---|

| overstock product | No |

| Product Type | Simple product |

| Lead time | Days |

| Pack Size | Each |

| UOM | EA |

| Is PLC | No |

| Description | UC-2400 Parts Counting System, Complete w/ ONE UC-2400 Part Counter, T-1000-S14 Advanced Poly-Bagger, Ti-1000Z Inline Thermal Printer, UF-2000 Takeaway Conveyor This system is a perfect industry solution for counting parts (no weighing) such as fasteners, electrical components, small molded parts and crafts items. Advanced Poly will evaluate your products by running them through our parts counters to confirm speed, accuracy, bag specification and system specifications. With this valuable information, you can decide whether this is a good solution for your company. Advanced Poly will configure each element of this system to produce the best production and accuracy results. For instance, vibratory bowl size can be from 15 to 36 inches based on your part size and we offer custom fabricated bowls for larger or unusual shaped parts. We offer reject gates, bulk "pre-feeder" hoppers, stack LED lights and other options for the parts counters. The bagger can be configured based on the smallest and largest bag size to optimize the opening consistency and other options added based on the weight or other characterist ics of the product. The printer is optional, but can also be configured with higher resolutions up to 600dpi and connection requirements. Finally, the conveyor can be configured based on the size of the bagged product, height of the discharge and other down-stream operations. As a "stock" system, our UC-2400 system includes standard options and accessories to package a wide variety of fasteners and hardware. It is simple to setup (less than 5 minutes for new product) and offers job save/recipes for changeover in less than 2 minutes based on the experience of the operator. This system is one of our most popular systems for smaller counts (less than 50 parts per bag), of the same part per bag. This system can support up to four parts counters simply by placing them into position and connecting them with a single cable, making this system great for kits up to 4 part number per bag. Please contact APP Machine Sales for more information on this "Industry Solution" System. You can also find our "Product Evaluation" services under the Free Products group. Simply download, complete the form and send it to: MachSales@advancedpoly.com. We will then promptly provide a custom ized quote for the system (budgetary) and after evaluating product sent to us, a confirmed quote with complete equipment specifications, suggested bag sizes and estimated speeds and accuracy. |

Write Your Own Review