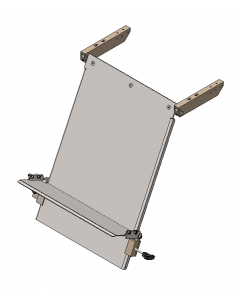

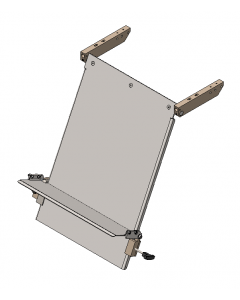

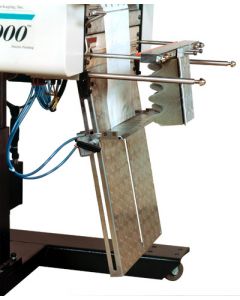

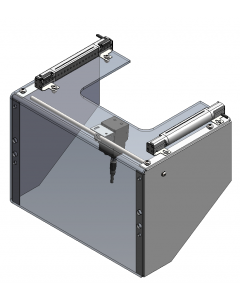

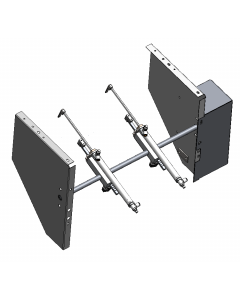

T-1000 Options and Accessories

Although the T-1000 is extensively equipped with many "built in" options, a full range of auxiliary options and equipment can easily be added for special purpose packaging or to improve your packaging operation.

Some of the available options are:

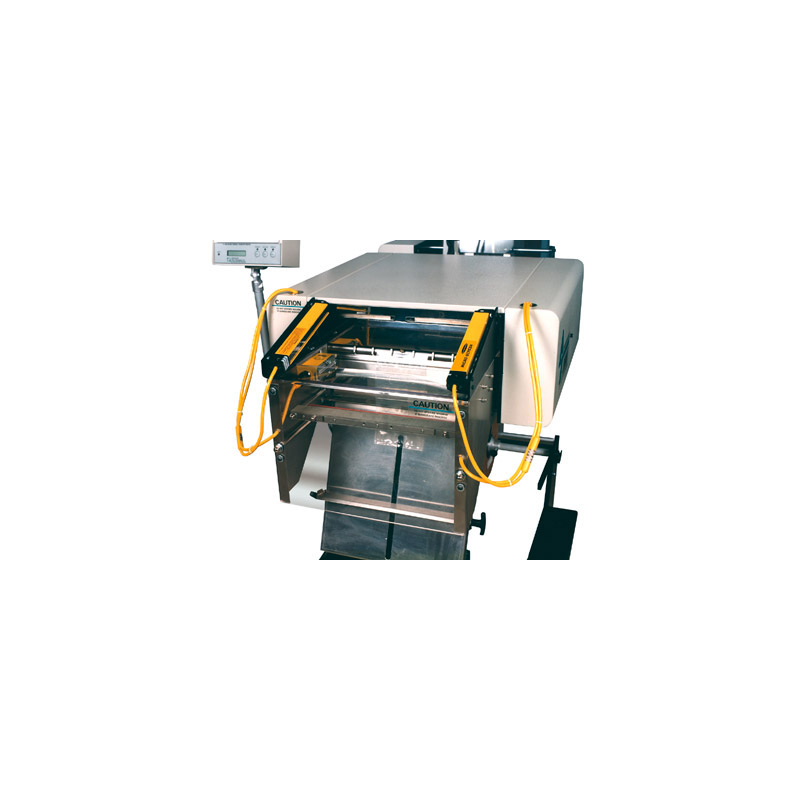

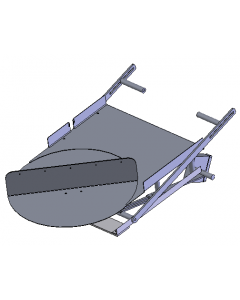

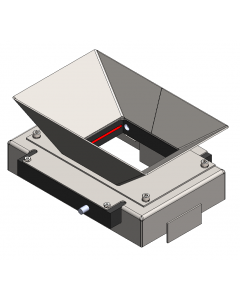

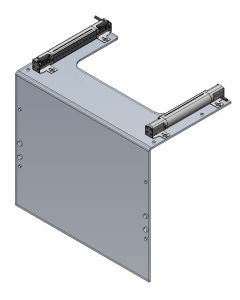

Light Curtains Counting Funnel

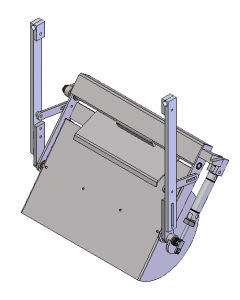

Partition Tables Load Shelves

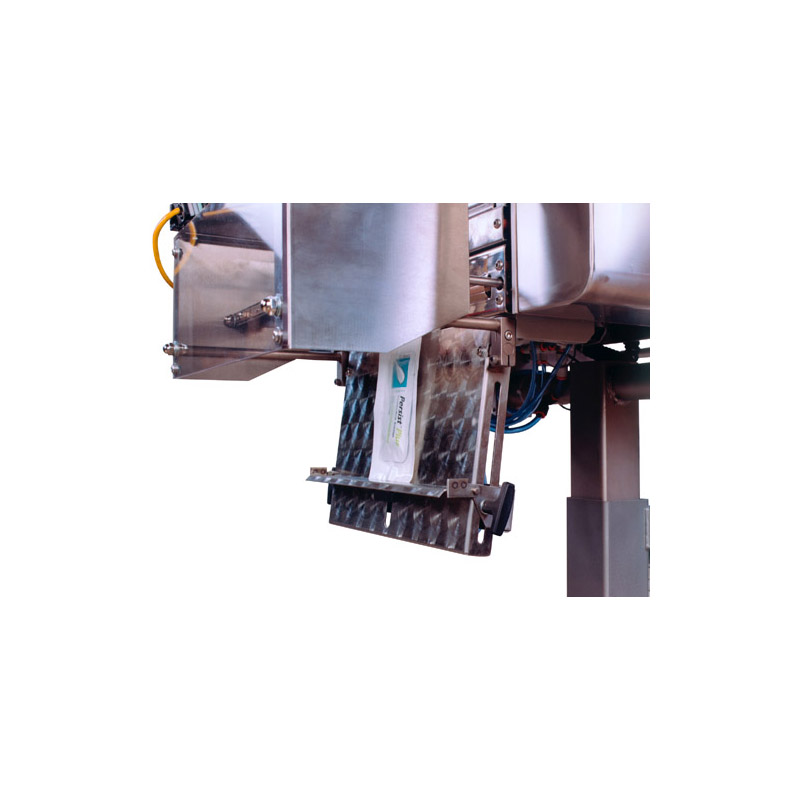

Bar Code Verifiers Optical Palm Buttons

Adjustable Carts Accumulating Funnels