T-1000 Options and Accessories

Although the T-1000 is extensively equipped with many "built in" options, a full range of auxiliary options and equipment can easily be added for special purpose packaging or to improve your packaging operation.

Some of the available options are:

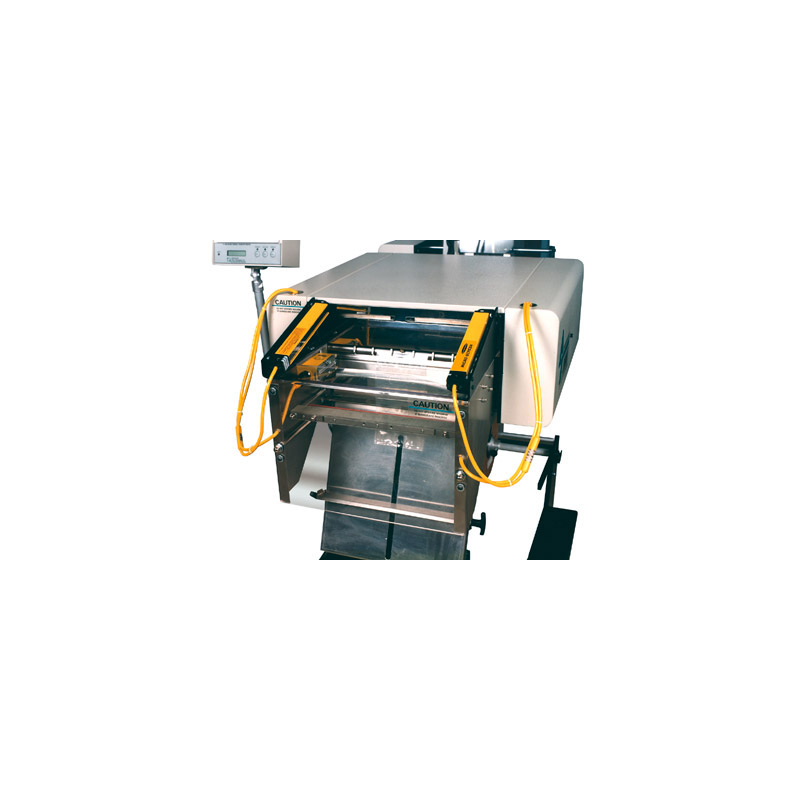

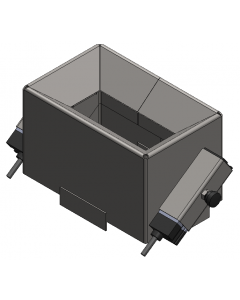

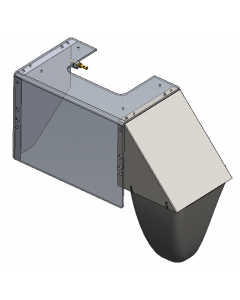

Light Curtains Counting Funnel

Partition Tables Load Shelves

Bar Code Verifiers Optical Palm Buttons

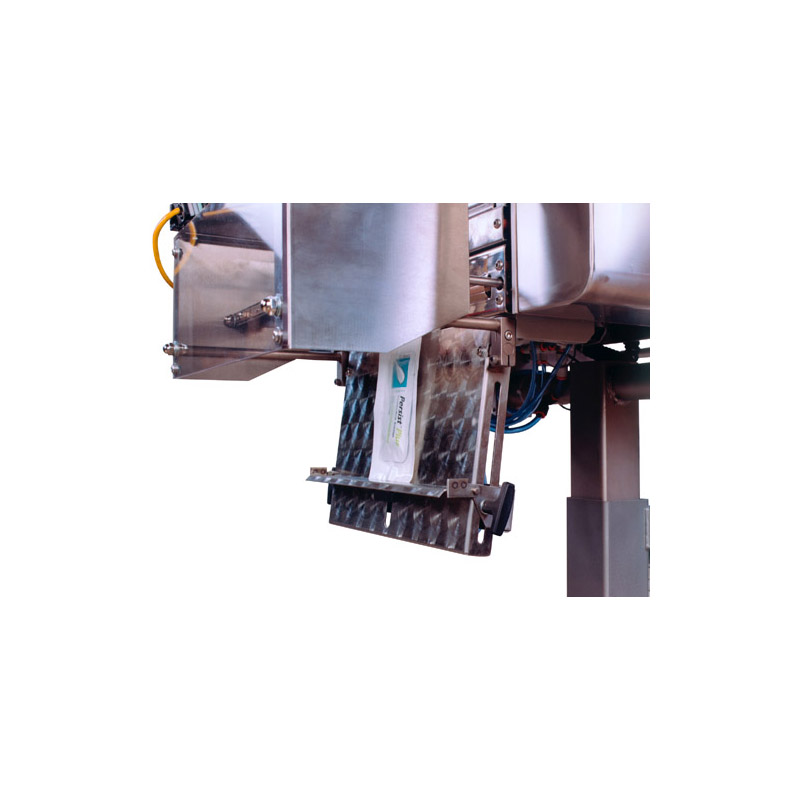

Adjustable Carts Accumulating Funnels